515TN

Nylon Cable Chain

- Chain

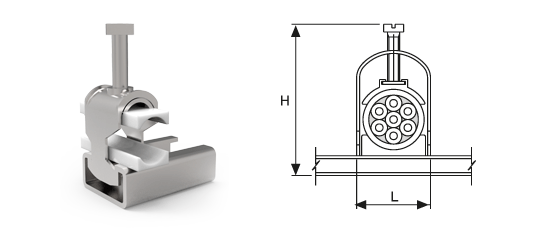

- End Brackets and Cable Clamps

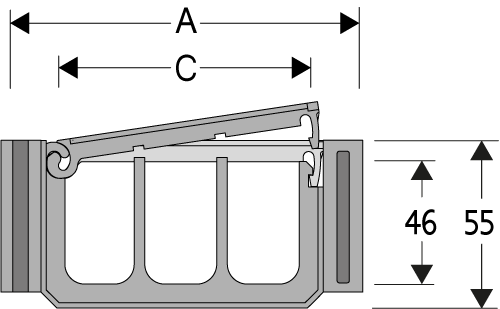

- GUIDE SUPPORT

- Materials

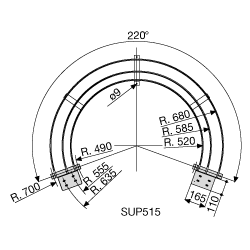

APPLICATION TYPE

Self Supported Stroke

Main dimensions

APPLICATION TYPE

Self Supported Stroke

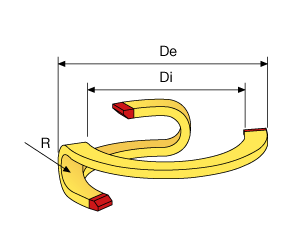

STEEL END BRACKET SET

Steel end bracket set completes both chian ends and allow for fastening on outer radius and inner radius: mounting position must be specified. Stainless steel can be delivered on request.

End brackets set for

END BRACKETS

TIEWRAP CLAMP

Guide support

For correct functioning of the chain it is necessary that the installation is done in a specific position. For this reason Brevetti Stendalto has observed and created a support guide which can do this. For particular applications it is possible to create support guides with attachment plates and special dimensions. For applications with rotations exceeding 200° it is necessary to use the appropriate accessories for supporting the cable chain.

BRYLON 6 TECHNICAL DATA

| Norms | Properties | Units | Dry | Conditioned |

|---|---|---|---|---|

| TERMICHE | ||||

| DSC | Melting point (10° C/min.) | °C | ||

| ASTM - D 696 | Coefficient of linear thermal expansion | X10-6 K-1 | ||

| ASTM D 648 ISO 75 DIN 53461 |

Heat distortion temperature ISO 75 1.82 N/mm2 °C 210 DIN 53461 0.45 N/mm2 |

°C °C |

210 220 |

|

| U. L. 94 | Flammability | H.B. | ||

| IEC 695-2-1 | Incandescent wire Temperature °C 650 Thickness |

650 3 |

||

| FLAMMABILITY | ||||

| ASTM-D 257 | Volume resistivity | Ohm cm | 1015 | 1011 |

| ASTM-D 257 | Surface resistivity | Ohm | 1013 | 1011 |

| ASTM-D 149 | Dielectric strength | KV/mm | 22 | |

| ASTM-D 150 | Dielectric constant (10 Hz) | - | 3.8 | 4.5 |

| ASTM-D 150 | Dissipation factor (10Hz) | - | 0.02 | 0.09 |

| PHYSICAL PROPERTIES |

||||

| ASTM-D 792 | Density | g/cm3 | 1.38 | |

| ASTM-D 570 | Water absorption at 23°C in water for 24 hours | % | 0.90 | |

| MECHANICAL PROPERTIES | ||||

| ASTM-D 638 ISO R/527 DIN 53455 |

Tensile yield stress Ultimate elongation |

N/mm2 % |

195 2.6 |

115 4 |

| ASTM-D 638 ISO R/527 DIN 53457 |

Tensile modulus of elasticity | N/mm2 | 10600 | 6900 |

| ASTM-D 790 ISO 178 DIN 53452 |

Flexural strength | N/mm2 | 310 | 190 |

| ASTM-D 790 ISO 178 |

Flexural modulus | N/mm2 | 10500 | 6800 |

| ASTM-D 256 | Unnotched Izod impact strength | J/m | 140 | 300 |

| ISO 180/4C | Notched Izod impact strength | KJ/m2 | 110 | 125 |

| ASTM-D 785 | Rockwell hardness | Scala R | 122 | 114 |

CHEMICAL RESISTANCE

| BRYLON 6 | BRYLON 6 | STEEL | ||

|---|---|---|---|---|

| Chemical agents | Concentration % | Amorphous | Crystal | |

| Methyl acetate | 100 | RB3 | RB2 | RB |

| Acetone | 100 | RB4 | RB | RB |

| Acetic acid (aqueous solution) | 40 | AF | AF | AF |

| Acetic acid (aqueous solution) | 10 | AF | AF | AF |

| Acetic acid | AF | AF | AF | |

| Citric acid | 10 | AD 15 | RD | AD |

| Hydrochloric acid (aqueous solution) | 36 | S | S | S |

| Hydrochloric acid (aqueous solution) | 10 | AF | AF | S |

| Hydrochloric acid (aqueous solution) | 2 | AF | AD | S |

| Chromic acid (aqueous solution) | 10 | AF | AF | AF |

| Chromic acid (aqueous solution) | 1 | RD | RD | AF |

| Hydrofluoric acid | 40 | AF | AF | S |

| Formic acid (aqueous solution) | 85 S | S | AD | |

| Formic acid (aqueous solution) | 40 S | AF | AF | AD |

| Phosphoric acid (aqueous solution) | 10 | AF | AF | S |

| Oleic acid | 100 | RB3 | RB3 | RD |

| Sulphuric acid | 98 | S | S | S |

| Sulphuric acid (aqueous solution) | 40 | AF | AF | S |

| Sulphuric acid (aqueous solution) | 10 | AF | AF | S |

| Sulphuric acid (aqueous solution) | 2 | AF | AD | S |

| Tartaric acid (aqueous solution) | RD | RB | RD | |

| Water | RB10 | RB9 | RD | |

| Chlorine water | RD | RD | AD | |

| Ethyl alcohol | 96 | RD17 | RB3 | RB |

| Ammonia | 10 | RB11 | RB | AF |

| Petrol | 100 | RB1 | RB | RB |

| Bitumen | RD | RD | RB | |

| Potassium carbonate | 100 | RB | RB | AF |

| Sodium carbonate | 10 | RB10 | RB3 | AF |

| Ammonium chloride (aqueous solution) | 10 | RB | RB | AF |

| Calcium chloride (aqueous solution) | 20 | S | S | AF |

| Calcium chloride (aqueous solution) | 10 | RB | RB | AF |

| Sodium chloride | 10 | RB | RB | AF |

| Formaldehyde (aqueous solution) | 30 | RD | RB | AD |

| Fat | RB | RB | RB | |

| Milk | RB | RB | RB | |

| Mercury | RB | RB | RB | |

| Oils | RB | RB | RB | |

| Oil | RB | RB | RB | |

| Paraffin oil | RB | RB | RB | |

| Silicon oil | RB | RB | RB | |

| Diesel oil | RB | RB | RB | |

| Mineral oil | RB | RB | RB | |

| Ozone | AF | AF | AF | |

| Oil | RB | RB | RB | |

| Potassium hydroxide (aqueous solution) | 10 | RB9 | RB3 | S |

| Sodium hydroxide (aqueous solution) | 50 | RD | RD | S |

| Sodium hydroxide (aqueous solution) | 10 | RB5 | RB | S |

| Sodium hydroxide (aqueous solution) | 5 | RB9 | RB | S |

| Aluminium sulphate | 10 | RB | RB | AF |

| Soap (aqueous solution) | RB | RB | RB | |

| Tincture of iodine | AF | AF | AD | |

| Trichloroethylene | RD5 | RD4 | RB | |

| Vaseline | RB | RB | RB |

Legend

The table shows the resistance to chemical agents of BRYLON 6 and Steel. The number by resistance value side shows which is the % weight increase due to swelling.

RB - Very good resistance.

RD - Good resistance.

AD - Limited resistance.

AF - Poor resistance.

S - Soluble.

Amorphous - Polymer in amorphous state.

Crystal - Polymer in crystalline state.

PERFORMANCES

Temperature range: -30°C + 125°C

Speed: 180°/s

Acceleration: 180°/s2