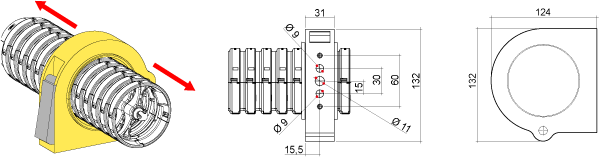

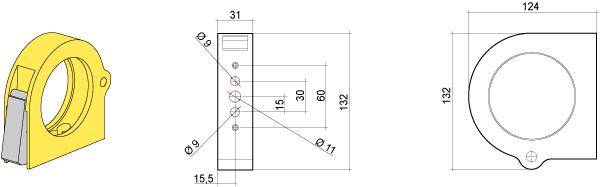

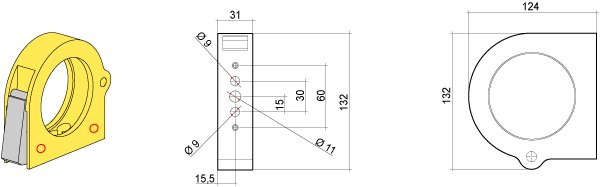

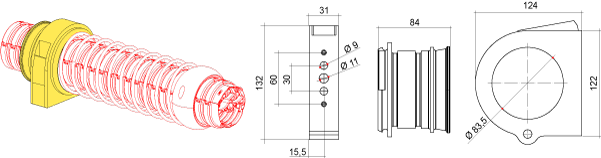

MFC65

Opening Nylon Chain - MULTIFLEX

- Chain

- Accessories

- Springs

- End plugs

- Materials

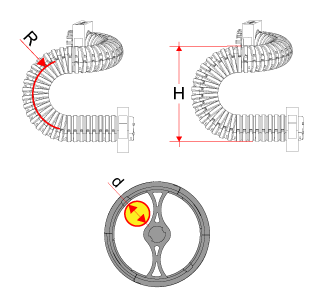

APPLICATION TYPE

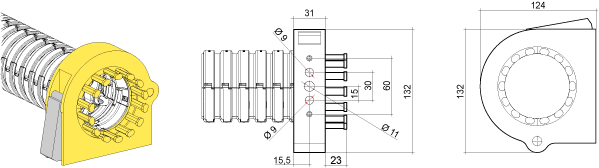

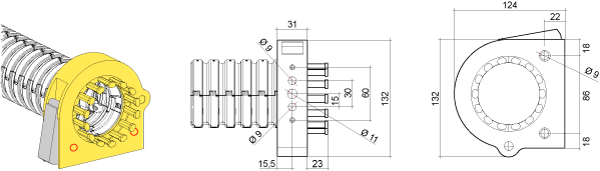

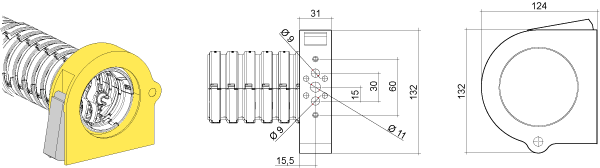

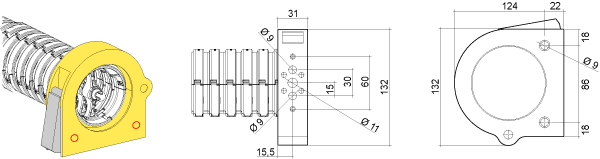

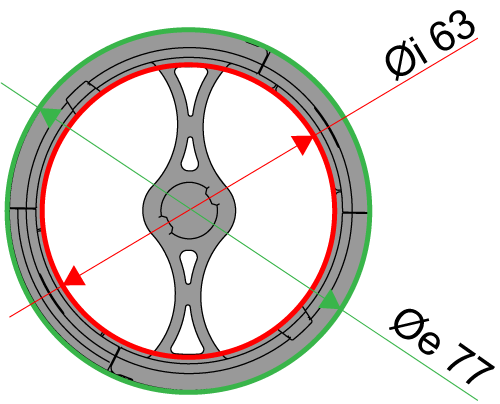

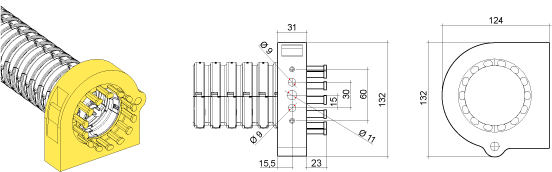

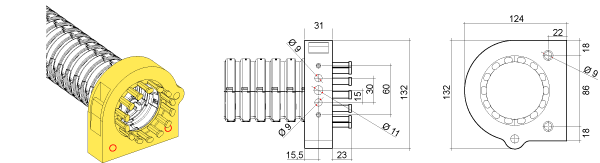

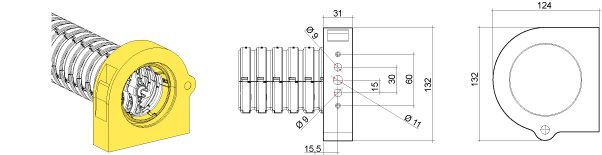

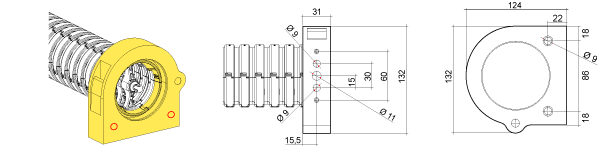

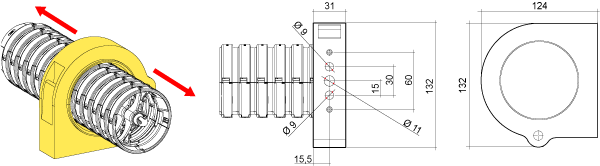

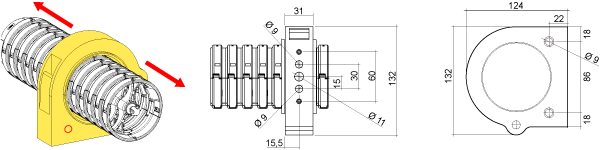

Main dimensions

Mounting Accessories

End clamps

Standard clamp set with plastic closing and cable combs for cable anchoring. This part number must be used at the end of the chian.

End clamps with cable combs - Front anchoring

Standard clamp set for front fastening with plastic closing and cable combs for cable anchoring.This part number must be used at the end of the chian.

End or intermediate clamps

Standard clamp set with plastic closing without cable combs. This part number can be used in any position on the chain.

End or intermediate clamps - >Front anchoring

Standard clamp set for front fastening with plastic closing without cable combs. This part number can be used in any position on the chain.

Sliding clamp

Clamp set for sliding with plastic closing . This part number can be used in any position on the chain.

Sliding clamp- Front anchoring

Clamp set for front fastening and sliding, with plastic closing . This part number can be used in any position on the chain.

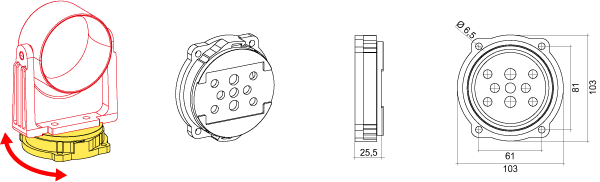

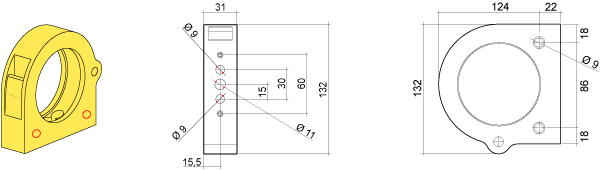

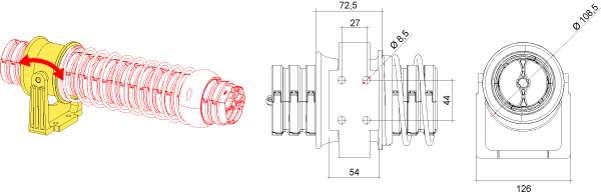

Rotating base

Pivoting flange tha can be used with any clamping device. This part number permits to any fastening clamp set and pivoting flange.

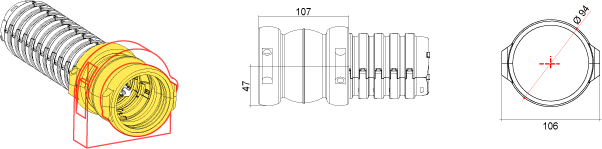

Guide support with sliding ring and pivoting.

Guide support with sliding ring and pivoting. Allow the user to impose a passage point of the chain, leaving all the degree of freedom in every moves.

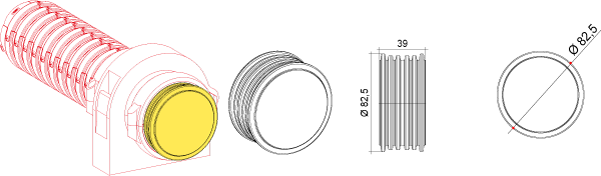

Protective ring

Protective and revolving ring, mounting anywhere on the chain. This part number protect the chain from bump, abrasion and wear.

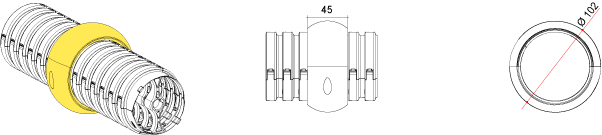

Connecting joint

Joint between Multiflex chain and conduit, or between Multiflex chain and cable star. This part number must be used with one of the anchoring clamps PASSB-70K o PASSB-70M.

End or intermediate clamps

Clamp set with plastic closing . This part number must be used with the part n. PAGB-70/8529.

End or intermediate clamps - >Front anchoring

Clamp set with plastic closing for frontal fastening. This part number must be used with the part n. PAGB-70/8529.

End or intermediate clamps - >Front anchoring

COM_STENDALTO_PASSB70K08583

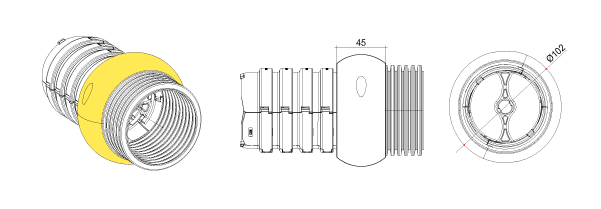

Globe Joint

Globe Joint that allow you to connect the Multiflex and conduit.

Fastening clamps for springs

Clamp set with plastic closing, to be used in combination with spring and protective ring. This part number must be used to define the reclaiming point of the chain.

Fastening clamps for springs

Clamp set with Zinc metal closing, to be used in combination with spring and protective ring. This part number must be used to define the reclaiming point of the chain.

Pivoting guide support for springs

Pivoting guide support with sliding ring to be used with spring and protective ring as per following image.

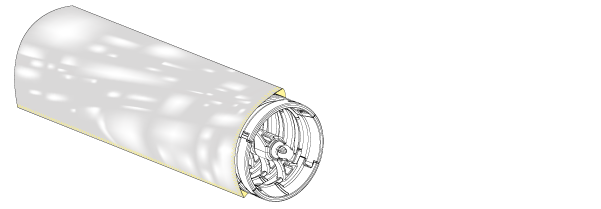

Kevlar protection

The heat protection jacket features an internal tissue made in Aramid/Kevlar, and an outer tissue made in aluminium. It is used to wrap the MULTIFLEX chain. It protects the chain from weld slags up to 540 °C, and reflects thermal radiations up to 95%.

Kevlar tissue offers good resistance against oils, greases, acids, bases, and solvents in low concentration. The outer tissue also has good resistance against UV rays.

Technical data:

Thickness: 0.35 mm

Specific weight: 1.44 / 1.45 g/cm3

Tear resistance: 2500 N/50 mm

Flammability: non-flammable (DIN 4102 B1)

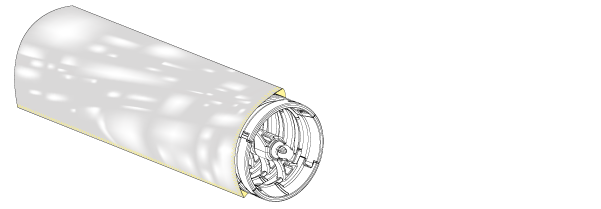

Kevlar openable protection - for static portion

The heat protection jacket with Velcro strap, features an internal tissue made in Aramid/Kevlar, and an outer tissue made in aluminium. It is used to wrap the MULTIFLEX chain. It protects the chain from weld slags up to 540 °C, and reflects thermal radiations up to 95%.

Kevlar tissue offers good resistance against oils, greases, acids, bases, and solvents in low concentration. The outer tissue also has good resistance against UV rays.

Technical data:

Thickness: 0.35 mm

Specific weight: 1.44 / 1.45 g/cm3

Tear resistance: 2500 N/50 mm

Flammability: non-flammable (DIN 4102 B1)

Reclaiming Springs

Reclaiming spring

Heavy spring for AMFM65K, AMFM65M, ASO65

Spring Rate 0,219 N/mm

Wire Ø 5 mm

Weight 1,5 kg/pc

Length L=1000 mm

Material Stainless Steel EN 10270-3/1.4310(X12 CrNi 1808).

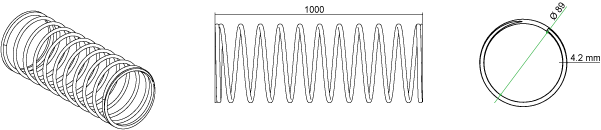

Reclaiming spring

Medium spring for AMFM65K, AMFM65M, ASO65

Spring Rate 0,108 N/mm

Wire Ø 4,2 mm

Weight 1,4 kg/pc

Length L=1000 mm

Material Steel EN 10270-1 SH sort C

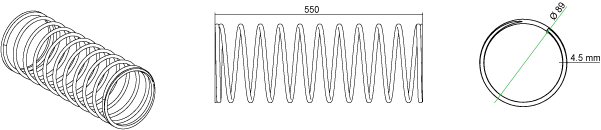

Reclaiming spring

Medium spring for AMFM65K, AMFM65M, ASO65

Spring Rate 0,246 N/mm

Wire Ø 4,5 mm

Weight 0,7 kg/pc

Length L=550 mm

Material Stainless Steel EN 10270-3/1.4310(X12 CrNi 1808).

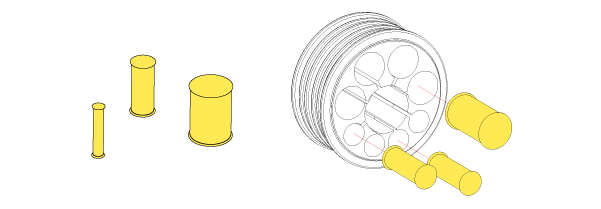

End plugs

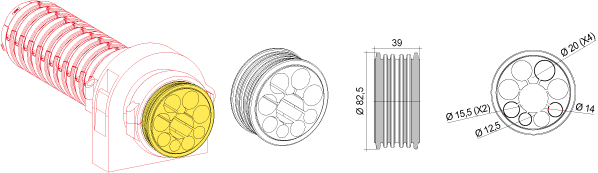

Cable star with holes

Cable star Ø 14 mm (x4)-Ø 20 mm (x4)

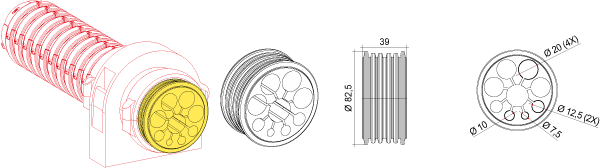

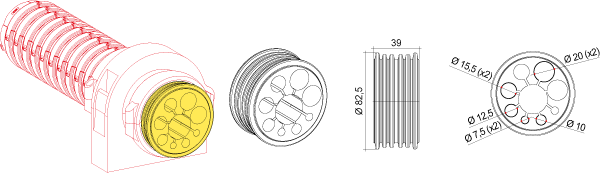

Cable star with holes

Cable star Ø 7,5 mm (x1) - Ø 10 mm (x1) - Ø 12,5mm (x2) - Ø 20 mm (x4)

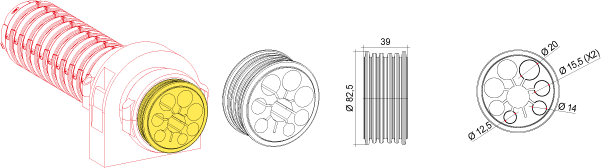

Cable star with holes

Cable star Ø 12,5 mm (x1) - Ø 14 mm (x1) - Ø 15,5 mm (x2) - Ø 20 mm (x3)

Cable star with holes

Cable star Ø 7,5 mm (x2)- Ø 10 mm (x1)- Ø 12,5 mm (x1)-Ø 15,5 mm (x1) - Ø 20 mm (x2)

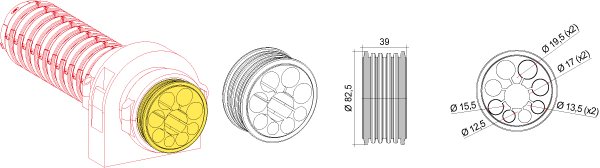

Cable star with holes

Cable star Ø 12,5 mm (x1) - Ø 14 mm (x2) -Ø 17 mm (x1) -Ø 18 mm (x3) - Ø 19 mm (x1)

Cable star with holes

Cable star Ø 12,5 mm (x1) - Ø 15,5 mm (x2) - Ø 17 mm (x1) - Ø 20 mm (x4)

Cable star with holes

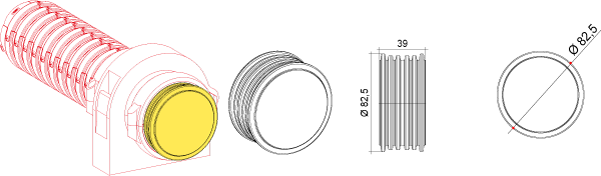

Cable star - no holes

Cable star with holes

COM_STENDALTO_TKKSB70BLIND

Closing end plugs

Plug for hole Ø 10 mm

BRYLON 6 TECHNICAL DATA

| Norms | Properties | Units | Dry | Conditioned |

|---|---|---|---|---|

| TERMICHE | ||||

| DSC | Melting point (10° C/min.) | °C | ||

| ASTM - D 696 | Coefficient of linear thermal expansion | X10-6 K-1 | ||

| ASTM D 648 ISO 75 DIN 53461 |

Heat distortion temperature ISO 75 1.82 N/mm2 °C 210 DIN 53461 0.45 N/mm2 |

°C °C |

210 220 |

|

| U. L. 94 | Flammability | H.B. | ||

| IEC 695-2-1 | Incandescent wire Temperature °C 650 Thickness |

650 3 |

||

| FLAMMABILITY | ||||

| ASTM-D 257 | Volume resistivity | Ohm cm | 1015 | 1011 |

| ASTM-D 257 | Surface resistivity | Ohm | 1013 | 1011 |

| ASTM-D 149 | Dielectric strength | KV/mm | 22 | |

| ASTM-D 150 | Dielectric constant (10 Hz) | - | 3.8 | 4.5 |

| ASTM-D 150 | Dissipation factor (10Hz) | - | 0.02 | 0.09 |

| PHYSICAL PROPERTIES |

||||

| ASTM-D 792 | Density | g/cm3 | 1.38 | |

| ASTM-D 570 | Water absorption at 23°C in water for 24 hours | % | 0.90 | |

| MECHANICAL PROPERTIES | ||||

| ASTM-D 638 ISO R/527 DIN 53455 |

Tensile yield stress Ultimate elongation |

N/mm2 % |

195 2.6 |

115 4 |

| ASTM-D 638 ISO R/527 DIN 53457 |

Tensile modulus of elasticity | N/mm2 | 10600 | 6900 |

| ASTM-D 790 ISO 178 DIN 53452 |

Flexural strength | N/mm2 | 310 | 190 |

| ASTM-D 790 ISO 178 |

Flexural modulus | N/mm2 | 10500 | 6800 |

| ASTM-D 256 | Unnotched Izod impact strength | J/m | 140 | 300 |

| ISO 180/4C | Notched Izod impact strength | KJ/m2 | 110 | 125 |

| ASTM-D 785 | Rockwell hardness | Scala R | 122 | 114 |

CHEMICAL RESISTANCE

| BRYLON 6 | BRYLON 6 | STEEL | ||

|---|---|---|---|---|

| Chemical agents | Concentration % | Amorphous | Crystal | |

| Methyl acetate | 100 | RB3 | RB2 | RB |

| Acetone | 100 | RB4 | RB | RB |

| Acetic acid (aqueous solution) | 40 | AF | AF | AF |

| Acetic acid (aqueous solution) | 10 | AF | AF | AF |

| Acetic acid | AF | AF | AF | |

| Citric acid | 10 | AD 15 | RD | AD |

| Hydrochloric acid (aqueous solution) | 36 | S | S | S |

| Hydrochloric acid (aqueous solution) | 10 | AF | AF | S |

| Hydrochloric acid (aqueous solution) | 2 | AF | AD | S |

| Chromic acid (aqueous solution) | 10 | AF | AF | AF |

| Chromic acid (aqueous solution) | 1 | RD | RD | AF |

| Hydrofluoric acid | 40 | AF | AF | S |

| Formic acid (aqueous solution) | 85 S | S | AD | |

| Formic acid (aqueous solution) | 40 S | AF | AF | AD |

| Phosphoric acid (aqueous solution) | 10 | AF | AF | S |

| Oleic acid | 100 | RB3 | RB3 | RD |

| Sulphuric acid | 98 | S | S | S |

| Sulphuric acid (aqueous solution) | 40 | AF | AF | S |

| Sulphuric acid (aqueous solution) | 10 | AF | AF | S |

| Sulphuric acid (aqueous solution) | 2 | AF | AD | S |

| Tartaric acid (aqueous solution) | RD | RB | RD | |

| Water | RB10 | RB9 | RD | |

| Chlorine water | RD | RD | AD | |

| Ethyl alcohol | 96 | RD17 | RB3 | RB |

| Ammonia | 10 | RB11 | RB | AF |

| Petrol | 100 | RB1 | RB | RB |

| Bitumen | RD | RD | RB | |

| Potassium carbonate | 100 | RB | RB | AF |

| Sodium carbonate | 10 | RB10 | RB3 | AF |

| Ammonium chloride (aqueous solution) | 10 | RB | RB | AF |

| Calcium chloride (aqueous solution) | 20 | S | S | AF |

| Calcium chloride (aqueous solution) | 10 | RB | RB | AF |

| Sodium chloride | 10 | RB | RB | AF |

| Formaldehyde (aqueous solution) | 30 | RD | RB | AD |

| Fat | RB | RB | RB | |

| Milk | RB | RB | RB | |

| Mercury | RB | RB | RB | |

| Oils | RB | RB | RB | |

| Oil | RB | RB | RB | |

| Paraffin oil | RB | RB | RB | |

| Silicon oil | RB | RB | RB | |

| Diesel oil | RB | RB | RB | |

| Mineral oil | RB | RB | RB | |

| Ozone | AF | AF | AF | |

| Oil | RB | RB | RB | |

| Potassium hydroxide (aqueous solution) | 10 | RB9 | RB3 | S |

| Sodium hydroxide (aqueous solution) | 50 | RD | RD | S |

| Sodium hydroxide (aqueous solution) | 10 | RB5 | RB | S |

| Sodium hydroxide (aqueous solution) | 5 | RB9 | RB | S |

| Aluminium sulphate | 10 | RB | RB | AF |

| Soap (aqueous solution) | RB | RB | RB | |

| Tincture of iodine | AF | AF | AD | |

| Trichloroethylene | RD5 | RD4 | RB | |

| Vaseline | RB | RB | RB |

Legend

The table shows the resistance to chemical agents of BRYLON 6 and Steel. The number by resistance value side shows which is the % weight increase due to swelling.

RB - Very good resistance.

RD - Good resistance.

AD - Limited resistance.

AF - Poor resistance.

S - Soluble.

Amorphous - Polymer in amorphous state.

Crystal - Polymer in crystalline state.